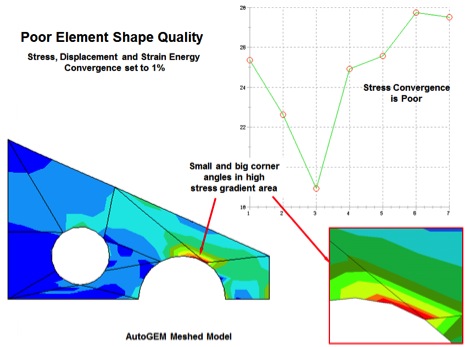

Generally Creo Simulate P-elements may be very poorly shaped with small or large corner angles (compared with conventional linear element codes) and still produce accurate results. The more poorly shaped the elements are the higher the P-level will have to be to get a certain level of accuracy. This is much more difficult through high stress gradient areas which also require higher P-levels. The typical indicators of this type of problem are erratic, unpredictable convergence plots.

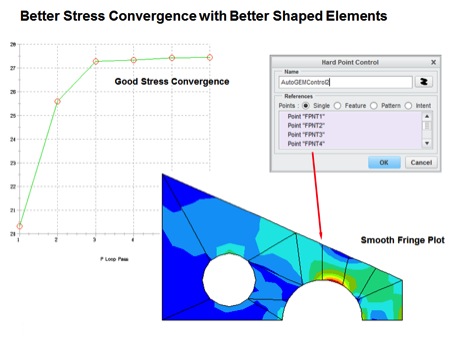

The solution to this problem is to force the mesher to create better quality elements. There are several methods that may be used. Usually these are very local problems and the best approach is to isolate the area in a way that will result in a better mesh. Strategic placement of Datum Points often works well. The mesher can be forced to put element corners at the points. Other methods include using Surface Regions, Volume Regions or by adding Mesh Control.

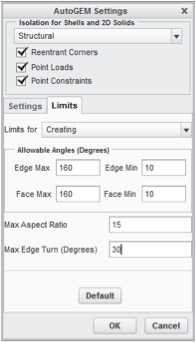

Another method is to globally control the element shape quality. This can be done using the AutoGEM mesher settings data form. If you change the corner angle range to something a little more conservative (10 to 160 degrees) and the maximum aspect ratio to a smaller value (maybe 15:1) the mesher will be forced to crate better quality elements. The only problem with this is that it will be a global change, which means that many more elements may be created than necessary. The more elements in the model the longer it will take to run. This settings change may also result in mesh failure because the mesher will have to work harder to create these better looking elements.